The essential takeaway: Modern logistics is abandoning the centralized cloud for Edge AI to escape the “latency trap.” By processing data directly on devices, warehouses achieve true swarm intelligence, allowing robots to make autonomous, instant decisions. This shift ensures safety and operational continuity, slashing critical reaction times from unpredictable lags to a reliable sub-10ms standard.

Is the hidden cost of network latency silently killing the efficiency of your automated logistics operations? This guide details why modern facilities are rapidly pivoting to edge ai smart warehouses, moving intelligence directly onto devices to bypass the cloud’s inherent delays. You will discover how this architectural shift eliminates the risk of robot paralysis and finally guarantees the instant, autonomous decision-making required to stay profitable.

Why the Cloud is Failing Modern Warehouses: The Latency Trap

Physics disagrees with your connection speed. Facilities are abandoning centralized processing for edge ai smart warehouses to escape the “latency trap.” Sticking with the old model doesn’t just lose milliseconds; it risks physical accidents.

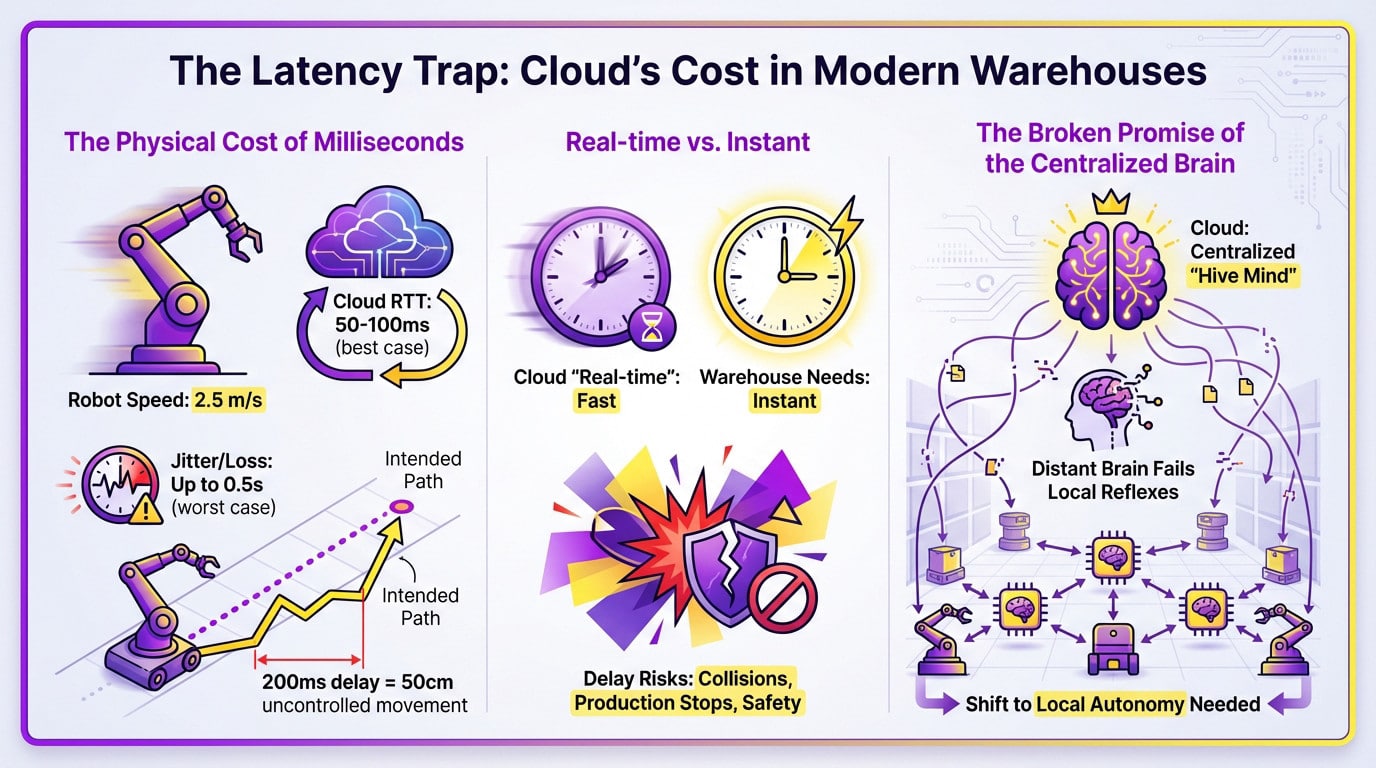

The Physical Cost of a Few Milliseconds

Smart warehouses are fleeing the cloud because of the latency trap. Consider a robot moving at 2.5 m/s; a mere 200ms delay means it travels 50cm without control. That is a crash waiting to happen.

The real culprit is Round-Trip Time (RTT). Even under the best conditions, sending data to the cloud and back takes 50 to 100ms. In logistics, that lag is an eternity.

Add network jitter or packet loss, and that delay spikes to 0.5 seconds. For precise automation, that is simply unacceptable.

When Real-Time Isn’t Just Fast, It’s Instant

We must stop confusing “cloud real-time” with the physical reality of a warehouse floor. In dense environments, decisions must be instantaneous, not just fast. You cannot afford to wait for a server to think.

A split-second hesitation triggers chain-reaction collisions, production stops, and safety hazards. Relying on the cloud’s “almost instant” speed is a massive operational gamble you shouldn’t take.

The Broken Promise of the Centralized Brain

Think of the traditional cloud model as a “Hive Mind” or centralized brain. It is powerful, sure, but fundamentally handicapped by physical distance. Distance kills the reflex speed required here.

A brain in a remote data center cannot manage the reflexes of a body miles away. That is why we need a shift to local autonomy. The warehouse must think for itself, right where the action happens.

The Great Migration: From a Centralized Hive Mind to Autonomous Swarm Intelligence

Now that we understand the latency trap, let’s look at the only viable solution: a hard pivot toward decentralized intelligence.

Introducing the Swarm: Decision-Making on the Device

Forget the outdated hive mind model entirely. We are shifting to swarm intelligence where every robot thinks for itself. They use on-device inference to make split-second choices locally. No more waiting for a central server’s permission.

This autonomy is possible thanks to powerful systems on modules (SoMs). Tiny chips like NVIDIA Jetson act as embedded mini-brains. They bring heavy computing power right to the robot’s edge.

How Local Processing Cuts the Cord

Local processing slashes response times to just a few milliseconds. It completely cuts the cord on internet dependency. Edge AI smart warehouses don’t care if the Wi-Fi drops.

“The goal is no longer to connect every device to a distant brain, but to give each device its own brain. That’s the only way to achieve true real-time responsiveness.”

- Maximum reliability: Operations keep running during network outages, which is vital during peaks like Black Friday.

- Enhanced security: Sensitive data stays on-site, reducing external breach risks.

- Accident prevention: Instant decisions stop collisions and errors before they actually occur.

Slashing Costs and Improving Scalability

Let’s talk about the bottom line. Edge processing drastically reduces bandwidth costs for modern logistics companies. You only send metadata or alerts to the cloud. There is zero need to stream heavy video footage 24/7.

This model is also infinitely more scalable for growth. Managing a fleet of 500 autonomous robots (AMRs) becomes manageable. You stop micro-managing data streams to a central server.

What Edge AI Looks Like on the Warehouse Floor

So, we have covered the theory of the “swarm,” but let’s get real. Here is what this technology actually looks like when the rubber meets the concrete in a modern facility.

Computer Vision: The New Barcode is No Barcode

Forget the handheld scanner. The real star of edge ai smart warehouses is computer vision. The goal is simple but ambitious: ditch the manual barcode scan entirely for passive, continuous tracking that never blinks. It is about moving from active logging to just… knowing.

Picture this setup: cameras are mounted everywhere—on conveyors, overhead gantries, or even clipped to workers’ vests. They aren’t just recording security footage; they are analyzing every single item that whizzes by in real-time.

Real-Time Identification and Error Correction

Here is the cool part. Powerful object detection models, like YOLO, run locally on the device itself rather than in a distant server. They identify packages instantly by their dimensions, brand logos, and even the text on the shipping label.

You see the benefit, right? If a package hops onto the wrong conveyor or sports a torn label, the system catches it instantly. It triggers an alert or a diverter immediately. This stops the error right there, preventing it from infecting the rest of the chain.

The Tangible Outcomes of Seeing Everything

This isn’t just about going faster; it is about surgical precision. When you stop relying on human scans, you stop losing money to silly mistakes.

Here is what happens when your warehouse actually sees what it is doing:

- Minimization of sorting errors: Packages actually end up where they belong, slashing those painful reshipping costs.

- Reduction of inventory loss: With passive tracking, items don’t just “vanish,” making losses practically impossible.

- Immediate anomaly correction: A crushed box gets flagged and pulled aside long before it reaches a disappointed customer.

Building the nervous system for the intelligent edge

5g isn’t the brain, it’s the nervous system

Stop assuming 5G does the heavy thinking. It acts not as the brain, but as the nervous system connecting every single endpoint. It transmits vital signals between “neurons” with zero hesitation. That is its only job.

Private 5G networks fit this role perfectly. They offer theoretical latency under 10 ms using a dedicated spectrum. Unlike Wi-Fi, they remain immune to interference inside dense, metal-filled warehouses. Your data never fights for signal.

The hardware and software stack that makes it work

You might wonder how this tech stack actually functions. We shift raw processing power directly to the device itself.

| Metric | Cloud-Based AI | Edge AI |

|---|---|---|

| Decision Latency | 50-500+ ms (unpredictable) | <10 ms (consistent) |

| Network Dependency | High (constant connection required) | Low (operates offline) |

| Bandwidth Cost | Very High (raw data streams) | Very Low (metadata only) |

| Data Security | Vulnerable during transit | High (data stays on-premise) |

| Scalability | Becomes a bottleneck with many devices | Scales linearly with devices |

Enabling true swarm collaboration

Private 5G unlocks genuine machine-to-machine (M2M) dialogue. Robots talk directly to each other, skipping the slow central server. This local link acts as the cement for true swarm intelligence. Speed defines their collective survival.

Picture a robot spotting a sudden spill. It instantly broadcasts a “no-go zone” to every other unit nearby. They reroute immediately without waiting for central command. That is edge ai smart warehouses in action.

The Warehouse as a Physical Neural Network

Solving the ‘Data Gravity’ Puzzle with Federated Learning

You can’t just upload terabytes of sensor logs to the cloud. It is a bandwidth nightmare. We call this “data gravity”—intelligence gets trapped because data is fragmented across hundreds of isolated devices, leaving your fleet dumb.

That is where Federated Learning fixes the mess. Instead of moving mountains of raw data, we just move the math. It allows edge ai smart warehouses to evolve collectively without killing the network.

- Each robot learns from its own experiences and updates its model locally.

- Instead of sending raw data, it sends only the “learnings” to a central server.

- The server aggregates these into a global model, which is then broadcast to the fleet.

From Smart Robots to Smart Floors: The Future Is Hyperlocal

Forget the “hive mind” metaphor where a central brain controls everything. The facility itself is becoming a physical neural network. Every sensor, camera, and forklift isn’t just a dumb terminal; they are active compute nodes contributing to global intelligence.

It gets wilder. We are seeing concepts like smart floors that process pressure data locally. They anticipate traffic jams or accidents before they happen, with zero need for a cloud round-trip.

The New Competitive Edge: Compute Density at the Periphery

Here is the hard truth: buying more robots won’t save you if they lag. The real advantage now lies in compute density at the periphery. That instant processing power is the engine driving the relentless speed of e-commerce logistics.

“In modern logistics, speed is everything. The battle for e-commerce dominance won’t be won in the cloud, but in the milliseconds saved on the warehouse floor.”

The era of waiting on the cloud is officially over. By moving intelligence to the edge, modern warehouses gain the reflexes needed for true automation. It’s not just about speed; it’s about survival in the e-commerce jungle. So, let’s cut the cord and let the robots think for themselves—before they bump into something.